AIRCRAFT GROUND POWER

These State of Art Power systems are used to provide 400Hz ground power to Parked Aircraft in Commercial Airports at Gate and Remote Parking bays, Maintenance Repair and Overhaul Hangars, and Airforce applications. Units are available in options as Mobile Diesel Ground Power Unit (GPU), Bridge or Ground Mounted self-contained Solid state units with In built Cable reel, and Stand alone vertical ground mounted Solid state Converters. Solid-state ground power units use power electronics to convert 50 or 60 Hz 230/400 V electric current into 400 Hz 115/200 V electric current with an output power between 45 and 180 kVA. The solid-state ground power units are available as floor-mounted, bridge-mounted or mobile electric versions and in combination with any connection system.

All Aircraft Types Narrow Body, Wide Body, Jumbo, and Different Military Aircraft needing 400Hz Power can be serviced with these systems. All units are equipped with modern control and monitoring systems, and can be integrated with Airport’s data monitoring system.

Some of the variants as below:

i. Diesel Ground Power Unit (Mobile):

These units are Mobile Trolley mounted, and can be operated to provide the Aircraft with required ground power. A Deutz diesel engine drives an electric generator which produces 400 Hz 115/200 V electric current. It is available from 90 kVA for narrow body aircrafts to 180 kVA for wide body aircrafts. Main components of the unit include a towable trolley with 4 x wheels, Diesel Engine, Converter, and 400Hz output flexible cable with Aircraft Connector.

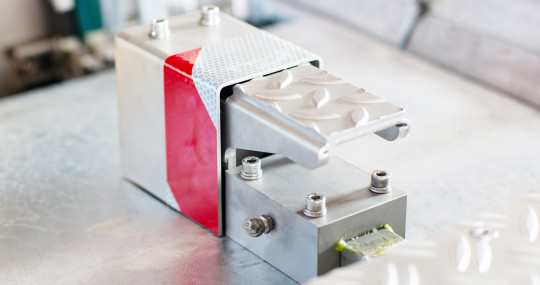

ii. Solid State Frequency Converter (with Integrated cable coiler):

These units need 3PH, 415 VAC, 50Hz supply and can be installed on a Passenger boarding bridge or a remote apron. Units are standardized in multiples of 90Kva, as each Aircraft single ground power connection is rated at this load.These units when installed underside of the Passenger Boarding Bridge’s Cab are easily accessible, and is an ideal solution for contact Gate parking position. Alternately, this unit can also be used at remote positions when installed on a pedestal. Main components of the units include 400Hz Converter, Motorized Cable coiler, Bridge Mounting stand, 400Hz flexible cable and Aircraft connector.

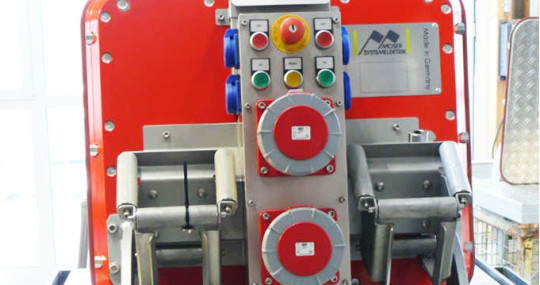

iii. Vertical Solid State Frequency Converter:

1. These units need 3PH, 415 VAC, 50Hz supply and can be installed at either contact stand, remote stand or MRO Hangar. Units are standardized at either 90Kva single output or 180Kva double output Units are vertical and floor mounted and can be ideal combination to be used with 400Hz Pit systems. Alternately, these units can also be used with Crocodile / Scissor systems or Cable Caddy system. This units is self contained, and is equipped with modern control and monitoring and can be easily integrated with Airport Data management system.

AIRCRAFT GROUND COOLING

Pre-Conditioned Air (PCA) systems are used to cool the aircraft or in other terms maintain the cabin temperature of parked aircraft while on ground. PCA system compliments 400Hz ground power, and are offered as one package in general.

These units can be Bridge Mounted or Ground Mounted and are mostly used to cool Aircraft at Commercial Airports, Maintenance Hangars and Military Tactical Aircraft.

These units are equipped with modern control and monitoring systems, and can be integrated with Airport’s data monitoring system.

Some of the variants as below:

i. PCA Unit – Air cooled DX (Bridge or Ground Mounted)

ii. PCA Unit – Water cooled (Ground Mounted)

iii. PCA Unit – Air cooled DX Mobile Electric

PIT SYSTEMS

PIT Systems are fabricated structures/enclosures most commonly used in combination with 400Hz, PCA, Potable water or and Blue water. These can contain 400Hz flexible cable(s), PCA Hose(s), Potable water/ Blue water hoses and electrical socket outlets. Such systems are Installed in concrete chambers, and are available in different options. De-Centralised Ground Mounted 400Hz or PCA systems designed using PITs are one of the best options compared to other popular options for reducing the Aircraft turn around time. Once installed, these systems are flush to the apron level and can be operated and maintained with ease. All these Pit systems are tested and comply with F900 load test.

Some of the variants for different applications include:

i. 400Hz Pit system

ii. PCA Pit system

iii. Electrical/Utility Pit system

AIRCRAFT FUELING

A Fuel Hydrant system is installed in an Airport, and such system is used to optimize the refueling time. We supply various components on the fuel hydrant system right from the Aviation Fuel Farm upto the Aircraft stand. Equipment such as Hydrant Pit boxes and Valve Chamber Access Covers guarantee to withstand a single 200,000 pound (90720kg) load applied over a 200 square inch (1290cm2) tire foot print area placed any where on it (1000psi (70.3kg/cm2) rating). This represents a 4 to 1 safety factor. Our Fueling Systems enable faster refueling, thus reducing the turn around time of Aircraft.

Some of the variants for different applications include:

i. Hydrant Pit Box

ii. Hydrant Pit Valve

iii. Under Hydrant Isolation Valve

iv. High Point Vent Valve

v. Low Point Drain Valve

vi. Valve Chamber Access Covers

vii. Pantographs